- E-mail: info@hlhsheetmetal.com

- Tel: +86-189-2523-3140

- Dongguan Qile Model Technology Co, Ltd

(HLH Sheet Metal)

Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

Quote & Order Terms: All quotes are estimates based on provided specs. Final price and lead time will be confirmed after drawing review.

Certifications: All certifications are held at our respective factory locations and can be verified upon request.

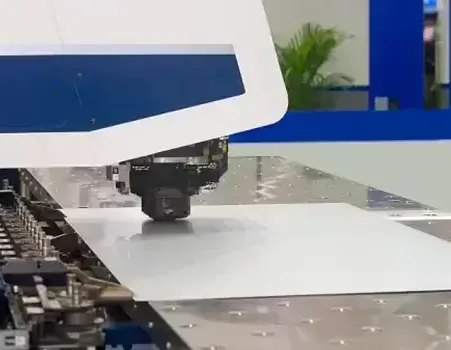

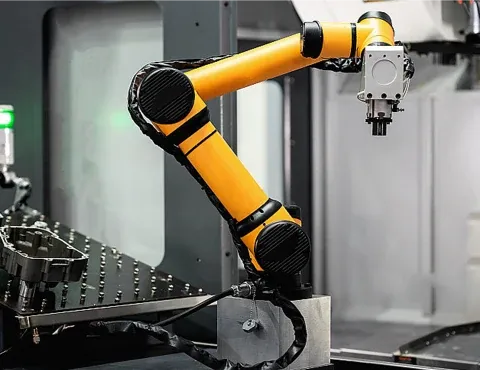

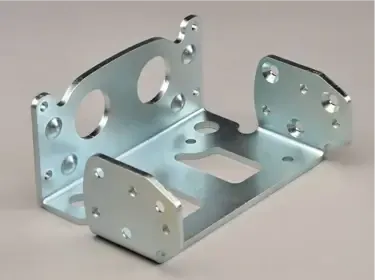

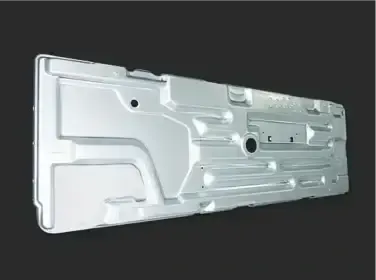

SHEET METAL FABRICATION

SERVICES

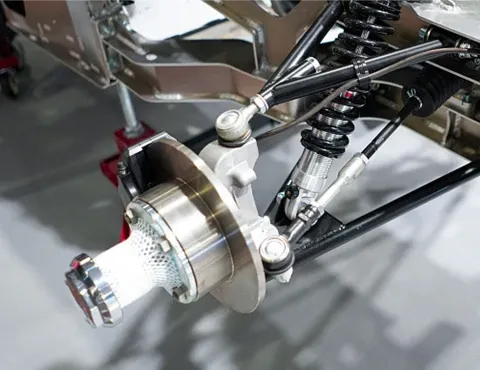

INDUSTRIES

Quote & Order Terms: All quotes are estimates based on provided specs.Final price and lead time will be confirmed after drawing review.

Certifications: All certifications are held at our respective factory locations and can be verified upon request.