- E-mail: info@hlhsheetmetal.com

- Tel: +86-755-2790-1779

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

| ✿ Tolerance as tight as ±0.05mm/100mm |

| ✿ The fastest processing parts 1 day |

| ➽ Mass production |

| ➽ Global Expertise |

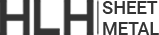

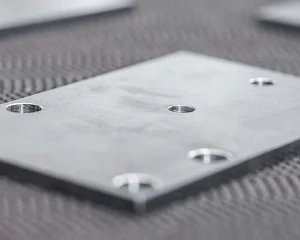

Laser cutting

Fast, accurate, clean laser cutting.

300+

Experienced Engineers

300+

Up-to-date Machines

30000+

Satisfied customers

12000+

Sq/m Manufacturing Facility

At HLH Sheet Metal, we specialize in delivering high-quality, precision laser cutting services that ensure your designs come to life with accuracy and speed. Our cutting-edge technology and expert team enable us to handle projects of any complexity, providing superior results for businesses across all industries.

Achieving tolerances as tight as ±0.05mm.

Minimal material waste with advanced technology.

Fast turnaround times to meet tight deadlines.

Tailored solutions for unique project needs.

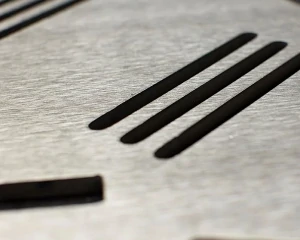

HLH's Laser cutting services can cut complex shapes. Our automated laser cutting process can handle any kinds of complex designs.

Laser cutting technology processes materials with thicknesses of up to 0.75”, ensuring versatility for a variety of applications.

We work with a wide range of materials, including ABS, Acrylic, Aluminum, Copper, Bronze, Brass, Delrin, HDPE, Nylon, Polycarbonate, PEEK, Polypropylene, PTFE, Stainless Steel, Steel Alloys, Titanium, UHMW PE, PVC, Thermal Pads, Transfer Tapes, Adhesive Sheets, and more.

Our state-of-the-art laser cutting machines are designed to deliver exceptional performance, whether it’s for intricate designs or heavy-duty industrial parts. We can work with a variety of materials and handle projects of all sizes, ensuring that your components are manufactured to exact specifications.

Capable of cutting materials from as small a 8mm spacer and up to 2000* 4000 mm

Perfect for intricate and complex patterns.

Satisfied

Customers

Fast Turnaround

Times

Next- Gen

Solutions

Comprehensive

Support

Parrett Family

Date of experience:June 20, 2024

HLH is Great!

Powerful and easy to use website, quality parts, fast shipping, helpful feedback and responsive support. What more could you want?

Spenser Hoge

Date of experience:January 12, 2024

Thanks HLH!

I ran into an issue while trying to anodize the parts, and HLH helped me out a lot. The problem got solved and I ended up getting the anodizing free of charge. It really is a five star place. Thanks HLH!

Petr Colwell

Date of experience:April 16, 2024

I love this company so much!

I love this company so much! The user interface online is amazing. All the materials to choose from, the options, all the add ons everything is so so helpful.

We operate from four locations across China: Shenzhen (our headquarters), Dongguan, Changsha, and Wuhan. HLH Sheet Metal is a division of HLH Prototypes Ltd , based in Wuhan. Our state-of-the-art 12,000 sq/m (130,000 sq/ft) manufacturing facility is spread across six specialized zones, each dedicated to producing high-quality metal, plastic, and composite rapid prototypes for diverse industries. At HLH , we make things easier to bring your ideas to life.

Stainless steel, with at least 10% chromium by weight, is ideal for precision laser cutting services. Its durability and corrosion resistance make it perfect for creating critical components such as engine and exhaust parts, landing gear assemblies, and aircraft superstructures. Laser cutting ensures clean, accurate cuts for high-performance applications.

Aluminum’s exceptional strength-to-weight ratio makes it a popular choice for laser cutting services. Its excellent ductility, stiffness, and corrosion resistance are perfect for aerospace components, such as fuselage skins, wing ribs, and enclosures. Laser cutting delivers precise results for lightweight and high-load applications.

Copper’s superior thermal and electrical conductivity is ideal for applications requiring precision and efficiency. Laser cutting services provide clean, precise cuts for copper, ensuring components meet the highest standards in energy transfer and industrial applications.

Nickel’s malleability and chemical stability make it well-suited for laser cutting services. The accuracy of laser cutting ensures the creation of durable components with smooth edges, ideal for industrial and chemical applications.

Tinplate’s metallic luster and corrosion resistance benefit greatly from precision laser cutting services. This technique ensures flawless cuts for manufacturing containers like food cans, beverage cans, and artistic designs, maintaining the material’s exceptional quality and appearance.

With laser cutting at the core of our operations, we follow rigorous quality control processes—from factory audits to detailed part inspections. Our commitment ensures your laser-cut parts consistently meet the highest industry standards.

Your intellectual property is in safe hands with our laser cutting services. At HLH Sheet Metal, We implement strict measures to safeguard your designs, earning the trust of 27% of Fortune 500 companies for their most critical projects.

Our laser cutting capabilities are backed by certified manufacturing standards, including ISO 9001, ISO 14001, IATF 16949, and ISO 27001. Our certifications guarantee top-notch quality, environmental responsibility, and data security for your project.

We offer laser cutting services for a wide range of materials, including aluminum, steel, stainless steel, copper, brass, titanium, plastics, and more.