- E-mail: info@hlhsheetmetal.com

- Tel: +86-755-2790-1779

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

ISO-Certified Manufacturer Offering Laser Cutting, Bending, Stamping, and

Custom Surface Finishing for Global Appliance Makers

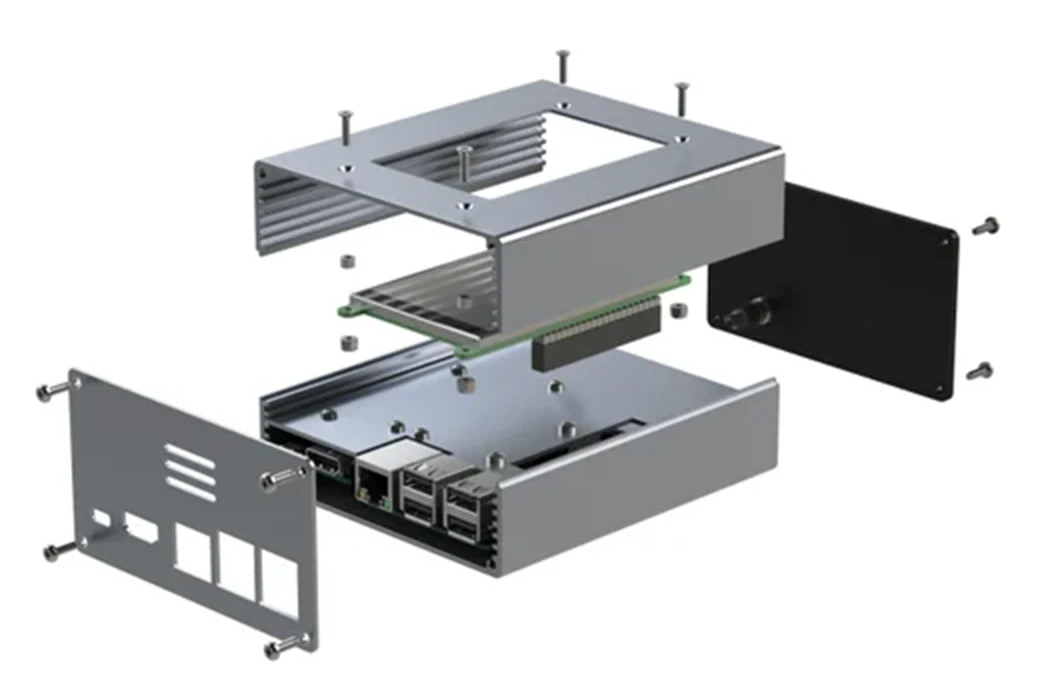

At HLH Sheet Metal , located in China, we specialize in sheet metal fabrication for appliances , providing precision parts, enclosures, component shielding, housings, chassis, mounting brackets, and more for HVAC, electrical and home appliances. With over 30 years of experience, our team of experts understands the complex requirements of the appliances manufacturing needs. We offer custom solutions that meet your unique specifications, from prototyping to mass production.

Our state-of-the-art facilities in China enable us to produce parts that are both durable and lightweight, tailored to the exact needs of your products. Whether you’re making HVAC, electronic appliances, industrial appliances or any other home appliances, HLH is your trusted partner for sheet metal fabrication.

From prototyping full-scale production, HLH offers end-to-end fabrication services to the appliances manufactures. Whether you need a single prototype to test your product or large-volume production runs for mass-market applainces, HLH has the capacity and expertise to deliver exactly what you need.

Test your designs with high-quality prototypes made from the same materials and processes used in full-scale appliances production.

Scale up to full production with confidence, knowing that HLH will deliver consistent quality and meet your delivery deadlines.

Our sheet metal prototyping services allow you to refine your designs before committing to full-scale production, saving time and costs in the long run.

"Don’t let fabrication challenges hold back your production. Request a quote today to see how HLH Sheet Metal can be your reliable partner for precision sheet metal fabrication for HVAC & Appliances. Let us simplify your manufacturing journey with quality, efficiency, and expertise."

Whether it’s bending, cutting, or stamping, HLH provides expert metal fabrication services tailored to your needs. We understand the importance of timelines. With facilities spread across China and reliable logistics , your parts arrive as scheduled. Work with an experienced provider who understands your needs!

Industry-Leading Certifications

Our expertise in metal fabrication ensures your HVAC & Appliances are built to perform at the highest level.

See How We’ve Delivered Precision and Reliability for Appliance Manufactures Worldwide

Parrett Family

Date of experience:June 20, 2024

HLH is Great!

Powerful and easy to use website, quality parts, fast shipping, helpful feedback and responsive support. What more could you want?

Spenser Hoge

Date of experience:January 12, 2024

Thanks HLH!

I ran into an issue while trying to anodize the parts, and HLH helped me out a lot. The problem got solved and I ended up getting the anodizing free of charge. It really is a five star place. Thanks HLH!

Petr Colwell

Date of experience:April 16, 2024

I love this company so much!

I love this company so much! The user interface online is amazing. All the materials to choose from, the options, all the add ons everything is so so helpful.

We offer a comprehensive range of services, including: Laser Cutting, CNC Machining, Stamping, Bending, Welding, and Professional Surface Finishing (Powder Coating, Anodizing, Painting, Deburring, and more) These services are tailored to meet the precise needs of the electrical & home appliance industry.