- E-mail: info@hlhsheetmetal.com

- Tel: +86-755-2790-1779

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

At

HLH Sheet Metal

, we specialize in providing

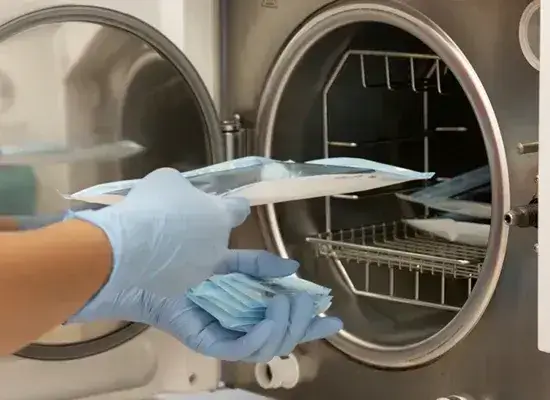

medical sheet metal fabrication

services that meet the highest standards of

quality precision

, and

regulatory compliance

. With over

30 years of experience

in manufacturing complex medical components, we are your trusted partner for delivering precision-crafted parts for medical devices. Our

ISO certified

processes ensure that every part we produce is of the highest quality, meeting all medical industry standards and regulatory requirements.

Whether you are in need of

medical sheet metal prototyping

or

full-scale production

HLH

delivers cost-effective, on-time, and reliable solutions tailored to your specific needs.

At HLH , we understand the critical role that surface finish plays in the performance and safety of medical components. We offer a range of professional surface finishing options, including:

Provides a durable, high-quality finish that is resistant to corrosion and wear.

Perfect for aluminum parts, anodizing enhances corrosion resistance while offering aesthetic appeal.

Ensures that all edges are smooth, and threaded holes are precisely created for easy assembly.

Our quality assurance processes ensure that each part meets both aesthetic and functional standards, providing you with medically compliant components you can trust.

From prototyping to full-scale production , HLH offers end-to-end fabrication services for the medical device industry. Whether you need a single prototype to test in a clinical trial or large-volume production runs for mass-market medical devices, HLH has the capacity and expertise to deliver exactly what you need.

Test your designs with high-quality prototypes made from the same materials and processes used in full-scale production.

Scale up to full production with confidence, knowing that HLH will deliver consistent quality and meet your delivery deadlines.

Our prototyping services allow you to refine your designs before committing to full-scale production, saving time and costs in the long run.

30+ Years of Expertise in Medical Metal Fabrication with Global Delivery

Certified Quality

Comprehensive Services

Global Delivery

Multilingual Communication

HLH

has been a leader in

medical sheet metal fabrication

for over

30 years

, with a proven track record of delivering high-quality parts to the

medical device industry

. Our large-scale facilities in

four major Chinese cities

allow us to serve

global customers

across various regions, including

North America

,

Europe

, and

Asia.

We understand the unique demands of the medical sector and are committed to ensuring that your parts meet compliance standards, specifications, and regulatory requirements.

Ready to get started? Contact us today for a custom quote for your medical sheet metal fabrication project. Our team of experts is ready to assist you in bringing your designs to life with precision , reliability, and compliance.

Quality, Compliance, Lead Time, Cost, and Communication

At HLH, we understand the critical nature of your concerns when choosing a sheet metal fabrication partner for medical equipment manufacturing . With over 30 years of experience in the industry and a strong commitment to quality, precision, and timeliness, we address your concerns with the following:

At HLH Sheet Metal , we are proud to be ISO certified, demonstrating our commitment to maintaining the highest standards of quality management in the medical device manufacturing process. Our medical sheet metal fabrication services comply with all relevant industry regulations, ensuring that every part we produce is safe, durable, and regulatory compliant. We work with medical-grade materials such as stainless steel, titanium, and aluminum, and each component undergoes quality control checks to guarantee compliance with FDA and other global standards. You can trust us to deliver parts that meet your exact specifications and are suitable for use in highly regulated medical applications.

We understand the pressure of meeting strict timelines in the medical industry. HLH Sheet Metal has four large manufacturing facilities in major cities across China, giving us the flexibility and capacity to manage both small-scale prototyping and large-volume production efficiently. Our experienced project management team ensures that all aspects of the fabrication process are well-coordinated, helping us meet delivery deadlines without compromising on quality. We provide clear lead time estimates and offer regular updates, so you can plan and manage your project with confidence. Whether it’s a prototype for clinical trials or full-scale production for mass-market distribution, we are committed to delivering on time, every time.

At HLH , we specialize in precision medical sheet metal fabrication . Our state-of-the-art equipment and advanced fabrication processes—including laser cutting, bending, stamping, and machining—allow us to produce complex medical components with tight tolerances and intricate designs. We have extensive experience working with a wide range of medical-grade materials, ensuring that the parts we produce are not only durable but also meet the specific performance needs of your medical devices. Whether you need parts for surgical instruments, patient monitoring systems, or MRI machines, we ensure that each component is crafted with precision and care, meeting the highest industry standards.

Effective communication is at the heart of everything we do at HLH Sheet Metal. We offer a single point of contact for each project, ensuring consistent communication throughout the process. Our project managers provide regular updates, tracking the progress of your project from design through to delivery. We maintain full transparency at every step, and should any issues arise, we have a clear escalation process in place to resolve them quickly. Additionally, our online project management tools allow you to access real-time updates, review drawings, and approve design revisions with ease. Our goal is to ensure that you feel confident and informed at every stage of the process.

300+

Experienced Engineers

300+

Up-to-date Machines

30000+

Satisfied customers

12000+

Sq/m Manufacturing Facility

At HLH Sheet Metal, we are ISO certified, ensuring that our manufacturing processes comply with international quality management standards for medical devices. This certification is crucial for producing parts that meet the stringent requirements of the medical industry. Additionally, we adhere to other relevant FDA and CE standards and ensure that all components meet medical-grade quality. Each part is subjected to rigorous quality control checks to guarantee safety, durability, and regulatory compliance.