- E-mail: info@hlhsheetmetal.com

- Tel: +86-755-2790-1779

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

| ➽ Expert sheet metal bending for complex geometries. |

| ➽ Rapid turnaround for prototypes and high-volume production. |

| ➽ Accurate, durable, and industry-compliant results. |

| ➽ 30 Years of Experience in Custom Sheet Metal Fabrication & Prototyping |

Bending

Utilising quality machines create excellent results.

300+

Experienced Engineers

300+

Up-to-date Machines

30000+

Satisfied customers

12000+

Sq/m Manufacturing Facility

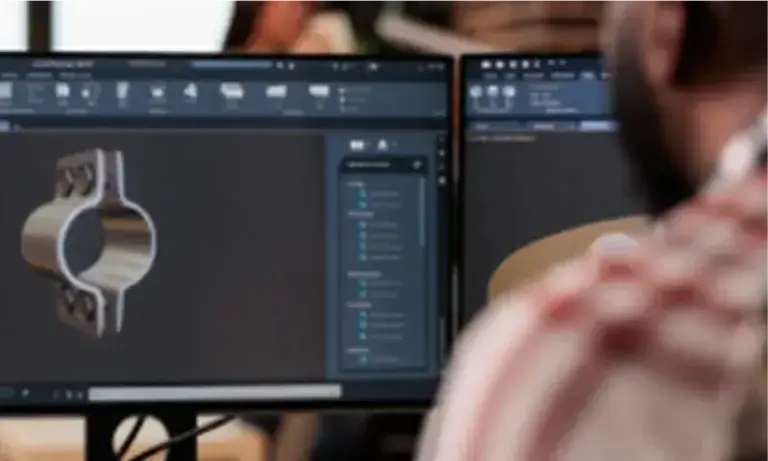

HLH Sheet Metal provides precise and efficient sheet metal bending services tailored to meet your project needs. Whether you require simple angles or intricate, multi-step bends, our advanced equipment and experienced team ensure exceptional results. From prototypes to large production runs, we deliver unmatched quality and accuracy. We’re committed to meeting your specifications, no matter the complexity of your project. Get precision, reliability, and efficiency with every project.

Advanced CNC bending machines ensure precision for every project.

Decades of experience in sheet metal bending services for various industries.

Tailored solutions to meet your specific requirements.

Sheet metal bending is a precision manufacturing process where flat metal sheets are expertly transformed into custom shapes by applying controlled force. Using advanced equipment like press brakes and panel benders, we create accurate bends, angles, and curves along a specific axis to achieve your desired geometry. At HLH Sheet Metal, our cutting-edge sheet metal bending services deliver unmatched accuracy and consistency, ensuring every part meets your exact specifications and exceeds expectations.

For precision and repeatability in every project.

Scalable solutions for large-scale production.

Tailored solutions for unique designs and geometries.

Rapid prototypes to accelerate your project timelines.

Achieving precise angles and shapes every time.

Efficient processes that reduce costs without compromising quality.

are designed to handle projects of any size.

Ensuring your bent metal parts are delivered directly to your door—on time and hassle-free.

Our sheet metal bending services are the go-to choice for industries like aerospace, medical, robotics, automotive, and more. We specialize in delivering customized solutions tailored to the specific demands of each sector. With precision and expertise, our custom sheet metal bending services are designed to meet and exceed the unique requirements of your industry.

Precision-bent components for aircraft structures and systems.

Durable parts for automotive prototypes and production.

ISO-compliant parts for medical devices and equipment.

Complex bends for robotic components and housings.

Reliable, high-quality components for appliances and systems.

Parrett Family

Date of experience:June 20, 2024

HLH is Great!

Powerful and easy to use website, quality parts, fast shipping, helpful feedback and responsive support. What more could you want?

Spenser Hoge

Date of experience:January 12, 2024

Thanks HLH!

I ran into an issue while trying to anodize the parts, and HLH helped me out a lot. The problem got solved and I ended up getting the anodizing free of charge. It really is a five star place. Thanks HLH!

Petr Colwell

Date of experience:April 16, 2024

I love this company so much!

I love this company so much! The user interface online is amazing. All the materials to choose from, the options, all the add ons everything is so so helpful.

We operate from four locations across China: Shenzhen (our headquarters), Dongguan, Changsha, and Wuhan. HLH Sheet Metal is a division of HLH Prototypes Ltd , based in Wuhan. Our state-of-the-art 12,000 sq/m (130,000 sq/ft) manufacturing facility is spread across six specialized zones, each dedicated to producing high-quality metal, plastic, and composite rapid prototypes for diverse industries. At HLH , we make things easier to bring your ideas to life.

Our sheet metal bending services cover a wide variety of materials, including: Steel Alloys, Stainless Steel, Aluminum, Copper, Brass, Nickel, Titanium and more, allowing us to cater to diverse industries. Whether it's the strength of steel, the lightweight properties of aluminum, or the conductivity of copper, we deliver precision and quality with every bend.

Strong and durable for heavy-duty applications. Stainless steel, containing at least 10% chromium by weight, is an ideal material for sheet metal bending fabrications. Known for its strength, corrosion resistance, and durability, it’s the preferred choice for critical applications like engine and exhaust components, landing gear assemblies, and aircraft superstructures. Our CNC bending services ensure precision and consistency, making stainless steel components fit seamlessly into your high-performance projects.

Aluminum stands out for its exceptional strength-to-weight ratio, making it a top choice for sheet metal bending in industries with high load requirements. Its lightweight properties, coupled with excellent ductility, corrosion resistance, and workability, make it ideal for applications like aircraft mounts, fuselage skins, wing ribs, and enclosures. Our CNC bending services deliver the precision required to shape aluminum into intricate, functional designs that meet your exact needs.

Excellent conductivity for electrical and thermal components. Copper is highly valued for its outstanding thermal and electrical conductivity, making it a versatile option for sheet metal bending parts. With excellent plasticity, corrosion resistance, and weldability, copper components are perfect for industries requiring heat or electrical efficiency. Our advanced CNC bending services handle copper with accuracy, delivering reliable, high-quality parts tailored to your specifications.

High-strength and corrosion-resistant for demanding environments. Nickel, known for its silvery-white appearance and durability, is a malleable and ductile metal ideal for demanding sheet metal bending applications. Despite its reactive nature, nickel forms a protective oxide layer, ensuring long-term stability. Through our CNC bending services , nickel components are crafted to meet stringent industrial requirements while maintaining their exceptional performance and quality.

Reliable and cost-effective for container manufacturing. Tinplate, a thin steel sheet coated with tin, offers a stunning metallic luster combined with superior corrosion resistance, solderability, and weldability. It is widely used for crafting containers like food cans, beverage cans, and artistic designs. Our sheet metal bending services transform tinplate into precise, high-quality components, meeting the diverse needs of industries that rely on its unique properties.

At HLH Sheet Metal , our sheet metal bending services are built on a foundation of excellence. From comprehensive factory audits to meticulous part inspections, we implement rigorous quality control measures at every step. Whether you're utilizing CNC bending for intricate components or standard bending for prototypes, we ensure that every part meets your exact specifications and the highest industry standards.

Trust is at the core of our sheet metal bending services . We take every precaution to safeguard your intellectual property, providing complete security and confidentiality for your projects. With 27% of Fortune 500 companies relying on us for their CNC bending and fabrication needs, you can be confident that your designs are in safe hands.

Our sheet metal bending services are backed by industry-recognized certifications to meet your project requirements. From ISO 9001 for quality management to ISO 14001 for environmental compliance, and IATF 16949 for automotive manufacturing, we deliver reliable, certified solutions. Whether it's a prototype or a large-scale project, our certified processes and advanced CNC bending technology ensure exceptional results.

Address your concerns with clear answers. Still have questions? Contact us today for personalized assistance.

We utilize advanced CNC bending techniques to ensure precise and repeatable results. This includes air bending, bottom bending, and coining, depending on the specific project requirements.