- E-mail: info@hlhsheetmetal.com

- Tel: +86-755-2790-1779

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

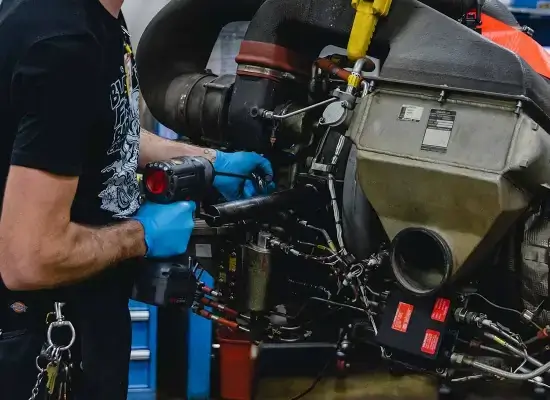

When it comes to aerospace sheet metal fabrication, precision and quality are non-negotiable. At HLH Sheet Metal , we specialize in aerospace sheet metal fabrication and prototyping with unparalleled precision and quality tailored to meet the exacting standards of the aerospace industry. From lightweight components to structural prototypes, our advanced CNC bending, stamping, laser cutting, and finishing services deliver components that meet the most stringent aerospace standards.

Will the parts meet aerospace

quality standards?

Can I trust you with my

intellectual property?

Will you deliver on time?

How can I ensure clear

communication?

Unmatched Quality, Compliance, and Expertise

With experience in working with materials like aluminum, stainless steel, titanium, and more, we guarantee precision fabrication that stands up to the rigorous demands of the aerospace industry. Whether it's fuselage panels, wing structures, or landing gear components, we’ve got you covered.

Trusted by global aerospace leaders for delivering high-quality, precision sheet metal components on-time.

We adhere to all relevant certifications, including ISO 9001, ISO 14001, AS9100, and IATF 16949, guaranteeing quality and compliance for your aerospace projects.

From one-off prototypes to mass production, we customize every order to meet your specific needs.

We understand the importance of safeguarding your designs. Trusted by Fortune 500 companies, we implement industry-leading IP protection measures to keep your proprietary data secure.

Time-sensitive projects demand fast turnarounds. We streamline our processes to ensure your sheet metal fabrication orders are completed and delivered on schedule without compromising quality.

We follow stringent quality assurance protocols, from factory audits to in-depth part inspections, ensuring every aerospace component meets the industry's highest standards. Your satisfaction is guaranteed every time.

Supporting a Range of Aerospace Needs.

We Meet the Unique Demands of the Aerospace Industry

From structural prototypes to custom-built UAV components, and fuselage panels to engine components, we provide tailored solutions for every aerospace application. Trust us for high-quality parts that are built to withstand the extreme demands of the aerospace environment.

Exterior skins

Interior sections

Cockpit sheet metal parts

Main rotor pylon parts

Cabin section

Aircraft tail section

Tail rotor pylon parts

Fuselage

Doors

Windows

Aircraft wings parts

Remove this space

Faceplates

Mounting systems

Panels

Switch brackets

Satellite components

Seats

Exhaust pipes

Drone parts, etc.

Industry-Leading Certifications

We meet all critical aerospace standards, ensuring your project is handled with the utmost professionalism and precision

300+

Experienced Engineers

300+

Up-to-date Machines

30000+

Satisfied customers

12000+

Sq/m Manufacturing Facility

Yes, we specialize in prototyping, offering fast turnaround times to help you validate your designs.