- E-mail: info@hlhsheetmetal.com

- Tel: +86-189-2523-3140

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

| ✿ Tolerance as tight as ±0.0004 "(0.01mm) |

| ✿ The fastest processing parts 1 day |

| ✿ Mass production |

| ✿ Global Expertise |

| ➽ Laser Cutting |

| ➽ Sheetmetal Bending |

| ➽ Stamping |

| ➽ Surface Finishing |

Laser cutting

Fast, accurate, clean laser cutting.

300+

Experienced Engineers

300+

Up-to-date Machines

30000+

Satisfied customers

12000+

Sq/m Manufacturing Facility

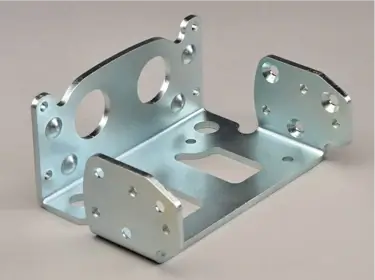

At HLH , we provide end-to-end sheet metal fabrication solutions designed to meet the highest industry standards.

From precision cuts to durable finishes, our advanced capabilities ensure your projects are delivered on-time, on-budget , and with superior quality.

Using state-of-the-art laser technology, we deliver clean, intricate cuts that perfectly match your custom designs. Ideal for projects requiring high accuracy and minimal material waste.

Our sheet metal bending services ensure components meet your exact specifications, no matter how complex. We guarantee precision and structural integrity for prototypes and production runs alike.

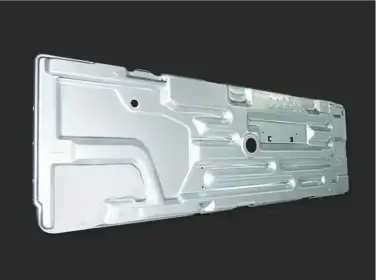

With efficient stamping processes, we deliver uniform, high-quality components at scale. Ideal for industries requiring reliable production with optimized costs.

Choose from powder coating, anodizing, painting, and other treatments to improve the strength, appearance, and longevity of your sheet metal components.

At HLH Sheet Metal , we pride ourselves on delivering high-quality, custom sheet metal fabrication solutions tailored to meet the unique needs of diverse industries.

From precision prototypes to large-scale production, our expertise ensures exceptional results for every sector we serve.

High Pricision

Standards

Fast Turnaround

Times

Global Expertise

Comprehensive

Support

Parrett Family

Date of experience:June 20, 2024

HLH is Great!

Powerful and easy to use website, quality parts, fast shipping, helpful feedback and responsive support. What more could you want?

Spenser Hoge

Date of experience:January 12, 2024

Thanks HLH!

I ran into an issue while trying to anodize the parts, and HLH helped me out a lot. The problem got solved and I ended up getting the anodizing free of charge. It really is a five star place. Thanks HLH!

Petr Colwell

Date of experience:April 16, 2024

I love this company so much!

I love this company so much! The user interface online is amazing. All the materials to choose from, the options, all the add ons everything is so so helpful.

ISO-certified manufacturing processes.

Comprehensive range of materials: aluminum, steel, copper, titanium, and more.

Large manufacturing facilities in 4 major cities in China.

End-to-end services, from design to delivery.

We operate from four locations across China: Shenzhen (our headquarters), Dongguan, Changsha, and Wuhan. Our state-of-the-art 12,000 sq/m (130,000 sq/ft) manufacturing facility is spread across six specialized zones, each dedicated to producing high-quality metal, plastic, and composite rapid prototypes for diverse industries. At HLH, we make things easier to bring your ideas to life.

Stainless steel, containing at least 10% chromium by weight, is an ideal choice for sheet metal fabrication and prototyping. Known for its durability and resistance to corrosion, it is commonly used in critical applications such as engine and exhaust components, landing gear parts, and aircraft superstructures. With its strength and reliability, stainless steel is a cornerstone material for high-performance industries.

Aluminum stands out in sheet metal fabrication due to its excellent strength-to-weight ratio. This versatile metal is perfect for aerospace applications, including fuselage skins, wing ribs, and enclosures requiring high-load capacity. Its superior ductility, corrosion resistance, and workability make it a go-to material for lightweight yet durable components.

Copper is a highly versatile material in sheet metal fabrication and prototyping , offering exceptional thermal and electrical conductivity. Its ductility and corrosion resistance make it a preferred choice for projects requiring precision and reliability. Additionally, copper's ease of welding allows for seamless fabrication of complex parts.

Nickel’s unique properties make it a valuable material in sheet metal fabrication . With its silvery-white finish, malleability, and durability, nickel is ideal for applications requiring corrosion resistance and long-lasting performance. Its protective oxide surface ensures stability, making it suitable for both industrial and commercial use.

Tinplate, a thin steel sheet coated with tin, is a popular material in sheet metal fabrication and prototyping . It combines a stunning metallic luster with excellent corrosion resistance, solderability, and weldability. Tinplate is widely used in manufacturing containers such as food and beverage cans, 18-liter drums, and artistic packaging solutions, offering durability with aesthetic appeal.

At HLH Sheet Metal , we offer a wide range of surface finishing services to complement our sheet metal fabrication and prototyping solutions .

From improving aesthetics to boosting durability, our finishing processes ensure your components are ready for real-world applications.

Delivering precision-engineered sheet metal fabrication and prototyping solutions ,

HLH Sheet Metal

ensures your parts exceed expectations, every time.

Trust us to deliver exceptional sheet metal fabrication services tailored to your exact specifications!

Precision You Can Rely On

Our rigorous quality control processes, from in-depth factory audits to meticulous part inspections, guarantee that your sheet metal fabrication and prototyping components consistently meet the highest industry standards. We prioritize accuracy and dependability in every project.

Your Designs Are Safe with Us

Protecting your intellectual property is a top priority. With advanced security measures and trusted protocols, we ensure your designs remain confidential, earning the trust of 27% of Fortune 500 companies for their sheet metal fabrication needs.

Certified for Your Success

Our sheet metal fabrication services comply with all necessary certifications to meet your project requirements. At HLH Sheet Metal, your project is backed by proven expertise and certified reliability. We comply with certifications including; ISO 9001, ISO 14001, IATF 16949, ISO 27001.

Lead times vary based on project complexity and volume. Standard projects typically take 1–2 weeks. Expedited services are available for urgent needs.