- E-mail: info@hlhsheetmetal.com

- Tel: +86-189-2523-3140

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

Aerospace sheet metal manufacturing is a highly specialized field that demands precision, reliability, and innovation. As the industry changes to meet strict performance and safety standards, manufacturers face challenges. These challenges affect production efficiency and quality. From material selection to complex fabrication processes, understanding these challenges is crucial for advancing aerospace manufacturing technologies.

Aerospace components require materials with exceptional strength-to-weight ratios, corrosion resistance, and heat tolerance. Commonly used materials include aluminum, titanium, and advanced composites. However, sourcing high-quality materials can be challenging because to supply chain disruptions, fluctuating costs, and stringent regulatory requirements.

Solution: Manufacturers can mitigate these challenges by developing strategic supplier partnerships, investing in material research, and leveraging alternative alloys that offer comparable performance.

The fabrication of aerospace components often involves intricate processes such as machining, welding, stamping, bending and additive aerospace manufacturing. Each of these methods has its own set of challenges, including precision requirements and the need for specialized equipment. For instance, machining titanium can be particularly difficult due to its toughness, which can lead to tool wear and increased production times. These processes must maintain consistency and meet aerospace-grade certification standards.

Solution: To address these issues, manufacturers can adopt advanced technologies like computer numerical control (CNC) machining and robotic automation. These technologies enhance precision and reduce human error, leading to improved production efficiency. Additionally, investing in employee training ensures that workers are skilled in the latest fabrication techniques, further enhancing quality and output.

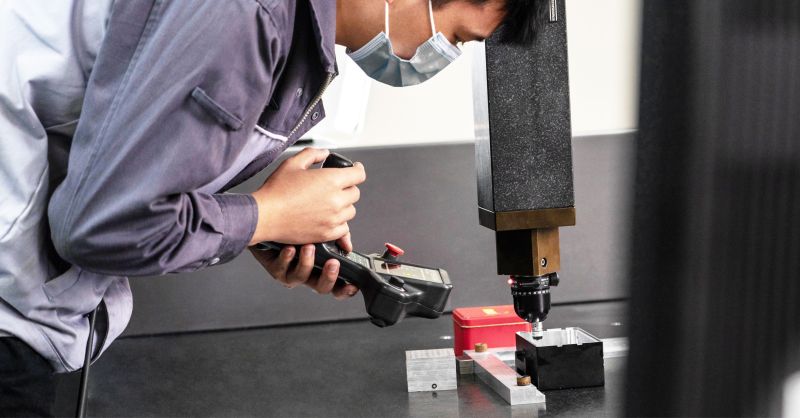

Ensuring the quality and reliability of aerospace components is paramount. The industry demands rigorous testing and inspection processes to meet safety standards. However, traditional quality control methods can be time-consuming and may not always catch defects early in the production process.

Solution: Implementing advanced quality control systems, such as real-time monitoring and data analytics, can significantly improve defect detection. By utilizing non-destructive testing methods and automated inspection technologies, manufacturers can identify issues before they escalate, ensuring that only the highest quality components make it to the final assembly.

Aerospace manufacturers must navigate a complex landscape of regulations and standards set by governing bodies. It includes AS9100, NADCAP, and FAA regulations. Compliance with these regulations is essential but can be a daunting task. It requires rigorous documentation, testing, and certification, especially for companies operating in multiple regions with varying requirements.

Solution: To streamline compliance, manufacturers can invest in compliance management software that helps track regulatory changes and ensures that all processes align with current standards. Additionally, fostering a culture of compliance within the organization can empower employees to prioritize safety and quality in their daily operations.

As environmental concerns grow, the aerospace industry is under pressure to adopt more sustainable practices. This includes reducing waste, lowering emissions, and utilizing eco-friendly materials. However, implementing these initiatives can be challenging without compromising performance or safety.

Solution: Manufacturers can explore innovative approaches such as recycling materials, optimizing production processes to minimize waste, and investing in research for sustainable alternatives. Collaborating with industry partners and participating in sustainability initiatives can also help drive collective progress toward greener manufacturing practices.

The aerospace industry operates under extremely tight tolerances, where even minor deviations can compromise component integrity. Ensuring precision in sheet metal fabrication requires advanced CNC machining, laser cutting, and forming techniques.

Solution: Implementing automated manufacturing systems, real-time quality control measures, and AI-driven predictive maintenance can enhance accuracy and reduce errors.

Aerospace manufacturers continuously seek ways to reduce weight while maintaining structural integrity. Traditional metals can be heavy, limiting fuel efficiency and performance.

Solution: Utilizing lightweight materials like titanium alloys and advanced composites, combined with precision sheet metal fabrication, helps achieve optimal weight-to-strength ratios.

The aerospace industry needs high-performance parts. However, advanced materials in aerospace and special fabrication methods raise production costs. This also leads to longer lead times.

Solution: Optimizing manufacturing workflows, investing in lean manufacturing principles, and utilizing rapid prototyping can help reduce costs and accelerate production timelines.

Talk to our experts. Our qualified engineers are always happy to answer your questions.

At HLH, we specialize in precision aerospace sheet metal fabrication, leveraging cutting-edge technology and expertise to overcome industry challenges. Our modern facilities and skilled engineers provide high-quality, compliant, and affordable solutions for aerospace needs. From prototype development to full-scale production, we provide tailored solutions that meet the industry's stringent requirements.

In the aerospace industry, the stakes are incredibly high. Every component must not only meet rigorous performance standards but also adhere to strict regulatory guidelines. This is where our expertise in aerospace sheet metal fabrication comes into play. We understand the unique challenges faced by manufacturers, from selecting the right lightweight materials to ensuring compliance with aerospace regulations.

One of the primary challenges in aerospace manufacturing is achieving precision in every part. Our advanced CNC machining capabilities allow us to create intricate designs with exceptional accuracy, ensuring that each component fits perfectly within the larger assembly. This precision is crucial, as even the smallest deviation can lead to significant issues in performance and safety.

Moreover, the demand for lightweight aerospace materials is ever-increasing. As the industry pushes for more fuel-efficient designs, we specialize in sourcing and working with advanced materials that provide the necessary strength without adding unnecessary weight. Our team is well-versed in the latest innovations in aerospace materials, enabling us to offer solutions that enhance performance while maintaining compliance with industry standards.

Welding and forming are also critical processes in aerospace manufacturing. Our skilled technicians utilize state-of-the-art techniques to ensure strong, reliable joints that can withstand the rigors of flight. We prioritize quality in every weld, understanding that the integrity of these connections is vital for the safety and reliability of the aircraft.

Additionally, rapid prototyping plays a significant role in our approach. By quickly developing prototypes, we can test and refine designs before moving to full-scale production. This not only accelerates the development process but also helps identify potential challenges early on, allowing for timely adjustments.

At HLH, we are committed to supporting your aerospace manufacturing needs with tailored solutions that address these challenges head-on. Our dedication to quality, precision, and efficiency sets us apart as a trusted partner in the aerospace industry. Contact us today to learn more about how we can help you navigate the complexities of aerospace sheet metal fabrication and achieve your manufacturing goals.

Our team of experts is always ready to collaborate with you, ensuring that your specific requirements are met with the utmost care. We understand that every project is unique, and we take the time to listen to your needs and provide customized solutions that align with your vision.

Moreover, our state-of-the-art facilities are equipped with the latest technology, enabling us to produce high-quality components that meet stringent aerospace standards. From initial design concepts to final production, we maintain rigorous quality control processes to ensure that every part we manufacture is reliable and durable.

In addition to our technical capabilities, we pride ourselves on our customer service. We believe that open communication is key to a successful partnership. Our team is always available to answer your questions, provide updates, and offer support throughout the entire manufacturing process.

As the aerospace industry continues to evolve, we remain committed to innovation and continuous improvement. We actively seek out new materials and techniques that can enhance our offerings and provide you with the best possible solutions.

Let us be your partner in success. Together, we can push the boundaries of aerospace manufacturing and achieve remarkable results. Reach out to us today, and let’s start a conversation about how we can turn your ideas into reality.

In conclusion, while the aerospace manufacturing industry faces numerous challenges, proactive strategies and innovative solutions can pave the way for improved efficiency, quality, and sustainability. By embracing new technologies and fostering collaboration, manufacturers can not only meet the demands of the industry but also contribute to a safer and more sustainable future.

Contact HLH today to discover how our custom sheet metal fabrication services can support your aerospace manufacturing needs.

Talk to our experts. Our qualified engineers are always happy to answer your questions.