- E-mail: info@hlhsheetmetal.com

- Tel: +86-189-2523-3140

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

SHEET METAL FABRICATION

INDUSTRIES

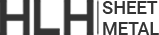

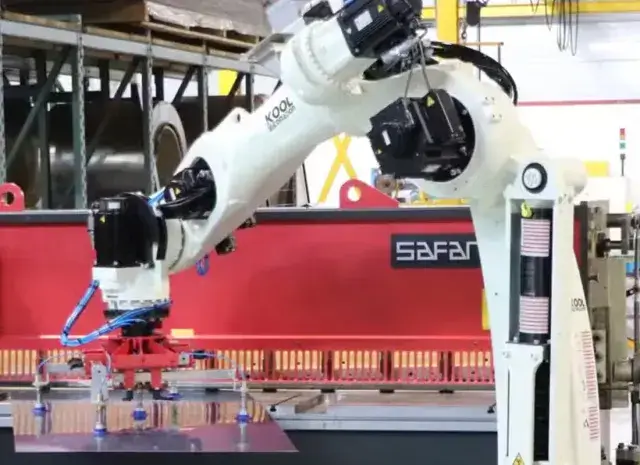

The manufacturing landscape is undergoing a significant transformation. Robotics in sheet metal manufacturing is at the forefront of this change.

These robotic systems are enhancing efficiency and precision in remarkable ways. They are revolutionizing the industry, performing repetitive tasks with high accuracy.

Industrial consultants, medical device designers, and product development managers are among those benefiting from this shift. They are leveraging robotics to overcome obstacles and optimize their operations.

However, the integration of robotics is not without its challenges. It requires a deep understanding of manufacturing processes and product design dynamics.

This article aims to shed light on the role of robotics in sheet metal manufacturing. It will explore the benefits, challenges, and future prospects of this technological advancement.

Join us as we delve into the world of robotics and its transformative impact on sheet metal manufacturing.

Robotics has become a pivotal component in the evolution of sheet metal manufacturing. Automation in this sector has progressed rapidly, transforming traditional workflows.

The ability of robots to perform repetitive and precise tasks is key to their rising adoption. This capability boosts productivity and significantly reduces errors.

Automation enables companies to maintain a competitive edge. By reducing labor costs and increasing efficiency, manufacturers can deliver higher-quality products.

Many businesses have realized that robotics is not just for large enterprises. Small and medium-sized companies also benefit from integrating these advanced systems.

As companies strive to meet rising market demands, robotics offer critical solutions. They support higher output, enhanced precision, and improved safety in manufacturing environments.

Talk to our experts. Our qualified engineers are always happy to answer your questions.

Robotics significantly enhance efficiency in manufacturing processes. Automated systems streamline complex tasks that are time-consuming for human workers.

Precision is another area where robotics excels, ensuring consistent quality. Robots achieve this through repeatable accuracy that minimizes variance in production.

Key benefits of implementing robotics include:

Robotics also allow for scalability in manufacturing operations. As demand fluctuates, robots can be reprogrammed to handle different tasks.

Moreover, robots offer flexibility through rapid adjustments in production settings. This adaptability is crucial for meeting dynamic market needs.

Industrial robotics play a vital role in smart manufacturing. They integrate with IoT and AI to enhance production capabilities. This combination leads to more intelligent manufacturing systems.

Smart manufacturing relies on data-driven insights. Robots collect and analyze data in real-time to optimize processes. This results in improved efficiency and reduced wastage.

The use of industrial robotics enables manufacturers to quickly adapt to changes. They ensure flexibility and agility in meeting market demands. This adaptability is key in maintaining competitiveness in a fast-paced industry.

Additionally, robotics streamline complex tasks, freeing human workers for strategic roles. This collaboration fosters an environment for innovation and continuous improvement.

China has swiftly embraced robotics in manufacturing. This rapid adoption is driven by the need to enhance productivity and cut costs. As a result, China stands as a global leader in automation efforts.

The integration of robotics has significantly improved manufacturing outcomes in China. Manufacturers benefit from reduced labor costs and increased product precision. This has strengthened China's competitiveness in the global market.

By investing heavily in robotic technologies, Chinese manufacturers ensure future growth. These investments support continuous advancements in automation. As a result, China maintains a strong position in the manufacturing industry.

Robotic welding has transformed sheet metal fabrication processes. It delivers consistent, precise welds that enhance product quality. Automation reduces human error, increasing manufacturing reliability.

The efficiency of robotic welding significantly speeds up production cycles. It enables rapid prototyping and fast market delivery. This efficiency is essential for industries like consumer electronics.

Robotics also improve workplace safety in welding operations. By performing hazardous tasks, robots reduce the risk of injuries. This leads to a safer and more productive working environment.

Introducing robotics in manufacturing may seem challenging at first. High initial costs can deter some businesses from adopting automation. However, long-term savings often outweigh these initial investments.

A critical factor for successful implementation is workforce training. Skilled workers are needed to manage, maintain, and troubleshoot robotic systems. Training and development initiatives are vital for bridging this skill gap.

Integration with existing systems can be complex. Ensuring compatibility between new robotic technologies and current machinery is crucial. Strategic planning and collaboration with robotics vendors can streamline this transition.

The future of robotics in sheet metal manufacturing looks promising. Advancements in technology will enhance precision and adaptability. This will result in faster production cycles and better quality.

Innovations in sensor technology and machine vision will drive these changes. These advancements will enable more complex and intelligent robotic systems. Manufacturers will benefit from improved accuracy and efficiency.

Collaboration between humans and robots, or cobots, is on the rise. This trend helps streamline operations and improve safety. The synergy of human expertise and robotic precision will define future manufacturing processes.

Embracing robotics in sheet metal manufacturing is no longer optional. The industry is evolving rapidly toward automation. Companies that adapt will stay ahead in the competitive market.

Integrating robotics offers significant advantages for manufacturers. It enhances efficiency, precision, and safety. These benefits help meet the growing demand for high-quality products.

As technology advances, the opportunities expand. Manufacturers need to invest strategically in robotic solutions. By doing so, they will not only improve their operations but also secure a more sustainable future.

Talk to our experts. Our qualified engineers are always happy to answer your questions.